Showroom

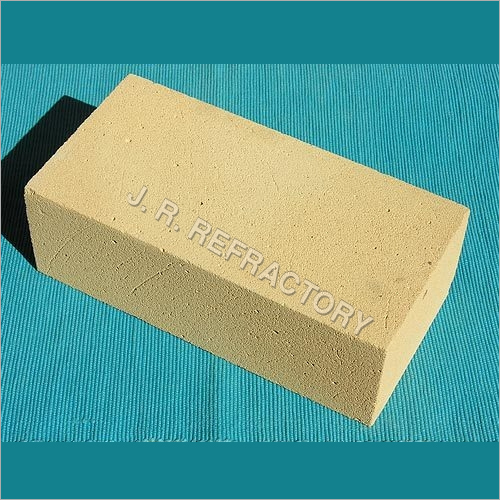

A fire brick is noted as a block of refractory ceramic material employed in lining kilns, fireboxes, furnaces, and fires. It can withstand high temperature with low thermal conductivity as well as greater energy efficiency.

Used for centuries for building warms and monuments, hollow bricks are now important products which are utilized in the construction inudustry. These clay-based blocks are durable enough to last a lifetime and can maintain stability under harsh climates.

Refractory Mortar is a non-metallic material having both chemical as well as physical properties that make it applicable for structures, or as mechanisms of systems, that can be exposed to environment.

Acid Proof Bricks are resistant to acid & alkali. These are made from special fully acidic raw physical of excellent chemical purity such as feldspar, china clay, quartz, etc.

Offered Refractory Castable can be utilized to produce the solid coatings inside a wide ambit of heaters as well as furnaces. It comes with strength and effectiveness.

Offered Refractory Bricks can be utilized to produce the solid coatings inside a wide ambit of heaters as well as furnaces. It comes with strength and effectiveness.

The compactness of Clay Bricks also enables them to show an effective acoustic insulation. Walls made from clay bricks obtain a supreme fire rating, meaning they can resist a fully developed fire for a substantial length of time in comparison to other building materials.

Shaped Bricks can meaningfully improve the aesthetics of a construction by rendering architects and builders with more freedom to transform in the arena of design. Beyond the plentiful aesthetic profits, Shaped Bricks can also deliver seamless functionality, additional durability and protection to masonry.

Modern refractory materials called Insulating Castables are created to offer superior thermal insulation in high-temperature industrial applications. These specialist castables are designed to endure extremely high temperatures while successfully reducing heat loss, making them a crucial part of several industries.

Refractory Tiles are heavy duty construction elements that are manufactured by using premium grade ceramic materials for the formation of various different types of structures that are capable to withstand high compressive loads and temperatures up to 540 degree Celsius.

Calcium Silicate Blocks are well known for their excellent structural stability, non combustible type design and non corrosive content. These re-usable and low maintenance blocks are completely free from lead, mercury and asbestos. Stable mechanical property is one of their main aspects.

Ceramic Fiber Blankets are well known for their strong thermal as well as acoustic attributes. These fire blankets can maintain stability of heat. Minimal shrinkage rate and excellent shock resistance capacity are some of the key characteristics of these insulated blankets.

Insulating Brick are the basic building units that are especially manufactured for high temperature applications as they are capable to resist impacts of heat very efficiently. These construction elements entraps air when they are made to provide excellent insulation.

Castable Refractory Cement is well known for its high compressive strength and long shelf life. This variety of cement is used to design boiler incinator, silicate furnace and cement kiln to name a few. This range of aluminate based cement is grey in color and it is accessible in fine dust form.

|

J. R. REFRACTORY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |